Cargo load transport trolley

| Model | Max Load (T) | Common Load (T) | Wheel Qty (pcs) | Measurement (mm) | NW (kg) |

| LWK-6 | 6 | 3 | 4 | 300*225*110 | 15 |

| LWK-8 | 8 | 4 | 6 | 400*225*110 | 21 |

| LWK-12 | 12 | 6 | 8 | 500*225*110 | 30 |

| LWK-15 | 15 | 7 | 9 | 400*313*110 | 32 |

| LWK-18 | 18 | 9 | 12 | 500*313*110 | 43 |

| LWK-24 | 24 | 12 | 16 | 550*380*115 | 65 |

| LWK-30 | 30 | 15 | 20 | 690*380*115 | 79 |

| LWK-36 | 36 | 18 | 25 | 690*462*115 | 95 |

Machinery Moving Trolley

| Model | No.of Wheels | Length of handle adjusting(mm) | Overall Size:(Length *Width*Height) | Capacity | N.W. | |

| (Ton) | (KG/PG) | |||||

| X4+Y4 | X4 | 4 | 800 | 230*230*110 | 8 | 31 |

| Y4 | 4 | 300-1000 | 170*140*110 | |||

| X8+Y8 | X8 | 8 | 1100 | 560*420*110 | 16 | 76 |

| Y8 | 8 | 400-1300 | 200*200*110 | |||

| X12+Y12 | X12 | 12 | 1100 | 750*450*110 | 24 | 106 |

| Y12 | 12 | 400-1400 | 256*200*110 | |||

| X16+Y16 | X16 | 16 | 1100 | 936*500*110 | 32 | 132 |

| Y16 | 16 | 400-1500 | 310*220*110 | |||

| X18+Y18 | X18 | 18 | 1500 | 780*500*110 | 36 | 148 |

| Y18 | 18 | 400-1500 | 300*250*110 | |||

| X24+Y24 | X24 | 24 | 1500 | 1000*580*120 | 48 | 200 |

| Y24 | 24 | 400-1600 | 360*315*120 | |||

| X32+Y32 | X32 | 32 | 1500 | 1080*720*140 | 64 | 312 |

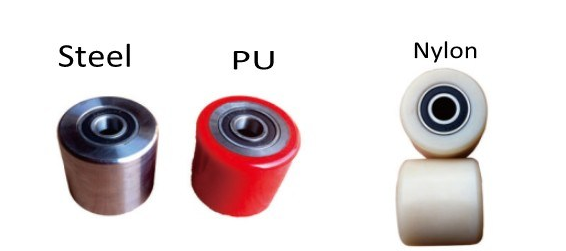

There are 3 kind wheels for you to select:

Application :

Point roller dolly system ? How does it work

Users unfamiliar with using a three point dolly system will hesitate because using 4 dollies is more intuitive. However, using a 3 point dolly system is in most cases more stable than using 4 dollies to transport a load.

If you are traveling over an uneven surface, your load will rock on 4 dollies just like a 4-legged chair on uneven ground.

When a load rocks on dollies that are not attached directly to it, the weight of the load is lifted off one dolly and it slips out.

This can cause obvious moving and safety problems.

Now, imagine a 3 +legged chair or stool; when it is placed on uneven ground, the chair will not rock. The 3 legged stool will

not lean or tip as long as the weight (Center of Gravity) is kept within the triangle created by the three legs.

Setting your load on three dollies will have the same effect: the load can not rock. Its weight has been evenly distributed,

pressing down onto the dollies at all times and thus keeping the dollies firmly in place.

Once your load is on three roller dollies, you can travel over uneven surfaces and not worry about the dollies slipping ?

even under pulling and tugging action.

Attention :

The rollers can be used on smooth & rough floors, on floors with cracks & dirt, inside & outside. The elastic rollers mold

around obstacles and keep rolling whereby overcoming small obstacles easily by – No stop, up & over action required

like with other rollers. The material spreads out intentionally for keeping low floor pressure. The rollers have low break

out & low rolling resistance with low push-pull force and low manpower requirements.

Benefits of Using a Cargo Load Transport Trolley

The benefits of using a cargo load transport trolley are numerous. Firstly, they help to reduce the risk of workplace injuries. By reducing the need for manual lifting and carrying of heavy goods, employees are less likely to experience back strain or other injuries. This, in turn, leads to increased productivity and reduced absenteeism.

Secondly, cargo load transport trolleys are incredibly versatile. They can be used in a variety of industries, including manufacturing, warehousing, and construction. They are suitable for transporting goods of all shapes and sizes, from small boxes to large machinery.

Finally, cargo load transport trolleys are an affordable investment that can pay for themselves many times over. By increasing efficiency and reducing the risk of workplace injuries, businesses can save money on labor costs and workers’ compensation claims.

Different Types of Cargo Load Transport Trolleys

Cargo load transport trolleys come in various types, each designed for specific applications. The most common types include:

Platform Trolley

A platform trolley is the simplest type of cargo load transport trolley. It consists of a flat platform supported by four wheels or casters. Platform trolleys are suitable for transporting boxes, small machinery, and other goods that don’t require additional support.

Hand Truck

A hand truck, also known as a dolly, is a two-wheeled cargo load transport trolley that is designed to carry heavy items up and down stairs. They are commonly used in the moving and delivery industry.

Pallet Jack

A pallet jack, also known as a pallet truck, is a cargo load transport trolley designed to lift and move pallets of goods. They are commonly used in the warehousing and logistics industry.

Forklift

A forklift is a powered cargo load transport trolley that is designed to lift and move heavy goods. They are commonly used in manufacturing and construction industries.

Factors to Consider When Choosing a Cargo Load Transport Trolley

When choosing a cargo load transport trolley, there are several factors to consider. Firstly, you need to consider the weight and dimensions of the goods you will be transporting. This will determine the size and capacity of the trolley you need.

Secondly, you need to consider the terrain and environment in which the trolley will be used. If you need to transport goods up and down stairs or over rough terrain, you may need a different type of trolley than if you are working on a flat surface.

Finally, you need to consider the ergonomics of the trolley. The handle should be at a comfortable height, and the wheels should be easy to maneuver.

How to Properly Use a Cargo Load Transport Trolley

Using a cargo load transport trolley is relatively straightforward. Firstly, you need to ensure that the goods you are transporting are securely fastened to the trolley. This will prevent them from falling off during transport.

Secondly, you need to ensure that the trolley is stable before moving it. This means checking that the wheels are locked in place and that the trolley is not overloaded.

Finally, you need to ensure that you are using proper lifting techniques when loading and unloading the trolley. This means bending your knees and lifting with your legs rather than your back.

Maintenance and Safety Tips for Cargo Load Transport Trolleys

To ensure the safe and efficient operation of your cargo load transport trolley, it’s essential to maintain it properly. This includes regularly inspecting the trolley for damage and wear and tear, lubricating the wheels and casters, and ensuring that the brakes are working correctly.

It’s also important to follow proper safety procedures when using a cargo load transport trolley. This includes ensuring that the trolley is not overloaded, using proper lifting techniques, and following all workplace safety regulations.