2) Thick gear cover is added with ribs, to enhance strength and protect inner structure.

3) Suspension and load hooks are with embedded design, and with reinforced safety latches.

4) All unpainted parts with high-grade corrosion protection.5) Main axle with ball bearing to minimize effort.

6) Low-wear sintered brake linings.

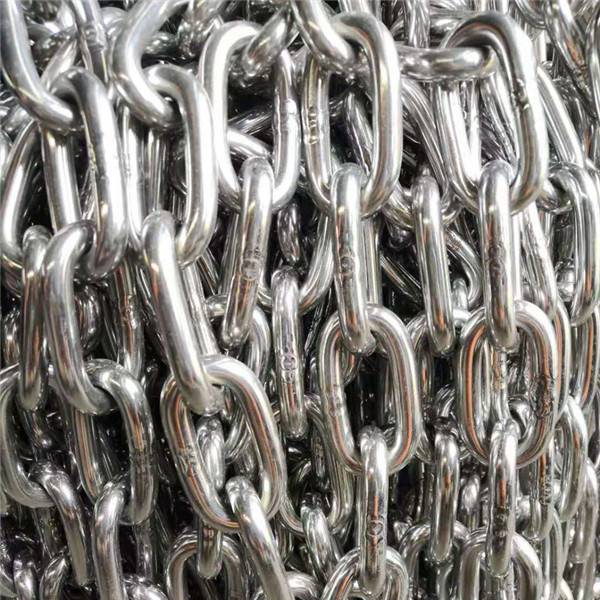

7) Load chain links for long life.

VT Type Manual Chain Block

| Model | VT 0.5 | VT 1 | VT 1.5 | VT 2 | VT 3 | VT 5 | VT 10 |

| Capacity(t) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 |

| Standard lifting height(m) | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Test load(t) | 0.75 | 1.5 | 2.25 | 3 | 4.5 | 7.5 | 15 |

| Min. headroom (hook to hook)(mm) | 285 | 315 | 340 | 380 | 475 | 600 | 740 |

| Chain pull to lift full load (kgf) | 25 | 33 | 34 | 34 | 35 | 39 | 41 |

| No. of load chain fall lines | 1 | 1 | 1 | 1 | 2 | 2 | 4 |

| Diameter of load chain(mm) | 6.3 | 6.3 | 7.1 | 8 | 7.1 | 9 | 9 |

| Net Weight(kg) | 8.3 | 11.3 | 13.5 | 21 | 22 | 40 | 77 |

Manual Steel Lever Hoist with Hook

| Capacity (t) | 0.75 | 1 | 1.5 | 2 | 3 | 6 | 9 | |

| Lift (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Test load (t) | 1.1 | 1.5 | 2.25 | 3 | 3.75 | 7.5 | 11.25 | |

| Pull to lift full load (N) | 145 | 150 | 200 | 200 | 280 | 310 | 320 | |

| Number of load chain | 1 | 1 | 1 | 1 | 1 | 2 | 3 | |

| Load chain dia (mm) | 6 | 6 | 7.1 | 8 | 10 | 10 | 10 | |

| Dimensions

(mm) |

A | 155 | 155 | 165 | 165 | 185 | 195 | 195 |

| B | 60 | 60 | 65 | 65 | 85 | 85 | 85 | |

| C | 135 | 135 | 145 | 145 | 195 | 250 | 335 | |

| D | 40 | 40 | 46 | 46 | 50 | 64 | 85 | |

| K | 24 | 24 | 31 | 31 | 34 | 43 | 55 | |

| H | 300 | 300 | 365 | 365 | 440 | 575 | 700 | |

| L | 255 | 255 | 365 | 365 | 365 | 365 | 365 | |

| Net weight (kg) | 7 | 7 | 10 | 12 | 18 | 28.5 | 45 | |

| Weight of extra chain each meter (kg) | 0.8 | 0.8 | 1.1 | 1.4 | 2.2 | 4.4 | 6.6 |

Feature

- The heavy duty top and bottom hook with casted safety latch.

- Double pawl to increase the safety protection and ensure the hoist for reliable operation.

- The ball bearing ensure the better mechanical efficiency.

- Overload protection device is available.

- Capacity Load: From 0.5T to 20T.

- Standard Lift: Fro 3M to 12M.

- High efficiency, small pulling effort and easy maintenance.

- Have good performance, easy to use and easy to repair.

- (be) reasonably structured, smooth running, good appearance.

Application

It is suitable for use in factories, mines, farms, construction sites, agricultural production, and in wharfs, docks and storages for fixing machines, lifting cargos, and loading and unloading goods.

It is especially advantageous for lifting work in the open air and places where no power supply is available.

The chain block can be attached to a trolley of any type as a traveling chain block. It is suitable to monorail overhead conveying system, handtravelling crane and jib crane.

Attention

* Overload limiter protects hoist mechanism is available.

* Wet friction discs with longer life.

* Wider opening hook of easier handling shape.

* Forged upper and bottom hooks with forged steel safety latches.

* Double pawls supporting fail-safe brake mechanism for secure operations.

How Does a Lever Hoist Work?

A lever hoist works by using a lever to control the movement of the load. The lever is connected to a chain that is wrapped around a drum. When the lever is pulled, the chain is pulled through the drum, causing the load to lift. The lever hoist is designed with a ratchet and pawl system that prevents the load from slipping or falling. The pawl engages the ratchet teeth, preventing the chain from slipping back, and the load from falling.

The lever hoist is designed with a brake system that prevents the load from dropping when the lever is released. The brake system is usually a disc brake that is activated when the lever is released, preventing the load from falling. The lever hoist is designed with a load chain that is made of high-quality steel that is durable and resistant to wear and tear.

Types of Lever Hoists

There are two main types of lever hoists: the manual lever hoist and the lever chain hoist. The manual lever hoist is designed with a lever that is used to lift or lower the load manually. The lever chain hoist, on the other hand, is designed with a chain that is used to lift or lower the load. The lever chain hoist is more efficient than the manual lever hoist, as it requires less effort to lift or lower the load.

There are also different sizes and capacities of lever hoists. The size and capacity of the lever hoist you choose will depend on the weight of the load you intend to lift. It is essential to choose a lever hoist that is capable of handling the weight of your load to avoid accidents and injuries.

Lever Hoist Capacity and Load Limit

The capacity of a lever hoist refers to the maximum weight that the hoist can lift. Lever hoists come in different capacities, ranging from 0.25 tons to 9 tons. The capacity of the hoist you choose will depend on the weight of the load you intend to lift. It is essential to choose a hoist with a capacity that exceeds the weight of your load to avoid accidents and injuries.

The load limit of a lever hoist refers to the maximum weight that the hoist can lift and hold without damaging the hoist. Exceeding the load limit of a lever hoist can cause the hoist to fail, leading to accidents and injuries. It is essential to check the load limit of the hoist before using it to avoid accidents and injuries.

Factors to Consider When Choosing a Lever Hoist

When choosing a lever hoist, there are several factors that you should consider. These factors include the weight of the load, the height you intend to lift the load, the frequency of use, and the environment in which the hoist will be used. It is essential to choose a lever hoist that is suitable for your needs to avoid accidents and injuries.

Another factor to consider when choosing a lever hoist is the brand. There are different brands of lever hoists in the market, and it is essential to choose a reputable brand that is known for its quality and durability. It is also essential to choose a lever hoist that comes with a warranty to ensure that you are protected in case of defects or malfunctions.

Lever Hoist Inspection and Maintenance

Like any other tool, a lever hoist requires regular inspection and maintenance to ensure that it is working correctly and safely. The hoist should be inspected before each use to ensure that it is in good condition and free from defects or malfunctions. The load chain should be inspected for wear and tear, and the brake system should be tested to ensure that it is working correctly.

The lever hoist should be maintained regularly to ensure that it is working correctly and safely. The load chain should be lubricated regularly to prevent wear and tear, and the brake system should be tested and serviced regularly to ensure that it is working correctly. It is also essential to store the hoist properly when not in use to prevent damage and ensure that it is ready for use when needed.

Proper Use and Safety Guidelines for Lever Hoists

To ensure that you use the lever hoist safely and correctly, it is essential to follow the manufacturer’s instructions and guidelines. The hoist should be used only for the purpose it was intended for and should not be used to lift or move loads that exceed its capacity. It is also essential to use the hoist in a safe and stable environment, free from hazards that could cause accidents or injuries.

When using a lever hoist, it is essential to wear appropriate personal protective equipment, including gloves and safety glasses, to protect yourself from injuries. It is also essential to ensure that the load is properly secured and balanced before lifting it to prevent it from falling or slipping. The lever hoist should be operated by a trained and competent operator who understands how to use the hoist safely.

Lever Hoist Accessories and Attachments

There are different accessories and attachments that can be used with a lever hoist to make it more versatile and efficient. Some of the accessories and attachments include beam clamps, trolleys, slings, and hooks. These accessories and attachments are designed to make it easier to lift and move loads in different applications.

When choosing accessories and attachments for your lever hoist, it is essential to choose those that are compatible with your hoist and suitable for your application. It is also essential to ensure that the accessories and attachments are of high quality and meet safety standards to avoid accidents and injuries.

Common Applications of Lever Hoists

Lever hoists are versatile tools that can be used in various applications, including lifting machines, moving heavy loads, and construction projects. Lever hoists are commonly used in the automotive industry to lift engines and transmissions, in the construction industry to lift and position heavy materials, and in the manufacturing industry to move heavy loads.

Lever hoists are also used in the entertainment industry to lift and position lighting and audio equipment, in the agriculture industry to lift and move hay bales and in the transport industry to load and unload cargo. Lever hoists are a handy tool that can be used in various industries and applications.