| Material | ship anchor chain steel (Q235/20Mn2/CM490/CM690) |

| Grade | one/ two/ three |

| Surface | Self color, black painted, galvanized |

| Produce Process | Drawings→ mould making → pre-forging →rough machining or finish machining →surface treatment →product checking and quality control→ packing →delivery |

| Lift-Sunny supply wide range of sizes and grades | Grade U1/ U2 / U3 from 12.5mm to 162mm; Grade ORQ / R3 /R3S / R4 from 58mm to 162mm. |

| d(φ) | CHAIN LINK SIZE | BM1 | BM2 | BM3 | APPROX. | |||||

| U1 OPEN LINK CHAIN | U2 OPEN LINK CHAIN | U3 OPEN LINK CHAIN | WEIGHT | |||||||

| 6d | 3.6d | PER | ||||||||

| DIAMETER | OUTSIDE | OUTSIDE | PROOF | BREAKING | PROOF | BREAKING | PROOF | BREAKING | 27.5M | |

| LENGTH | WIDTH | LOAD | LOAD | LOAD | LOAD | LOAD | LOAD | |||

| (in.) | (mm.) | (mm.) | (mm.) | (kn.) | (kn.) | (kn.) | (kn.) | (kn.) | (kn.) | (kg.) |

| 1/2 | 12.5 | 75 | 45 | 28.75 | 57.81 | 41.2 | 82.6 | 56.4 | 112.8 | 85.41 |

| 9/16 | 14 | 84 | 50.4 | 34.78 | 69.93 | 51 | 101.9 | 70.76 | 141.51 | 106.55 |

| 5/8 | 16 | 96 | 57.6 | 47.1 | 94.72 | 66.2 | 132.3 | 92.42 | 184.83 | 139.43 |

| 11/16 | 17.5 | 105 | 63 | 56.35 | 113.31 | 78.89 | 157.78 | 110.55 | 221.1 | 178.35 |

| 3/4 | 19 | 114 | 68.4 | 66.42 | 133.57 | 93.6 | 187.2 | 130.32 | 260.64 | 217.68 |

| 13/16 | 20.5 | 123 | 73.8 | 77.33 | 155.49 | 108.64 | 217.27 | 151.7 | 303.42 | 229.14 |

| 7/8 | 22 | 132 | 79.2 | 89.06 | 179.08 | 125.4 | 250.9 | 174.4 | 349.4 | 264.49 |

| 15/16 | 24 | 144 | 86.4 | 105.98 | 213.25 | 149.9 | 298.9 | 207.9 | 415.8 | 341.82 |

| 1-1/16 | 26 | 156 | 93.6 | 124.38 | 250.12 | 175.4 | 350.8 | 244 | 488 | 369.94 |

| 1-1/8 | 28 | 168 | 100.8 | 144.26 | 290.08 | 203.8 | 406.7 | 283 | 566 | 427.04 |

| 1-3/16 | 30 | 180 | 108 | 165.6 | 333 | 234.2 | 467.5 | 324.9 | 649.8 | 490.98 |

| 1-1/4 | 32 | 192 | 115.2 | 188.42 | 378.88 | 265.6 | 531.2 | 369.6 | 739.3 | 559.65 |

| 1-5/16 | 34 | 204 | 122.4 | 212.7 | 427.72 | 299.9 | 599.8 | 417.3 | 834.6 | 671.52 |

| 1-7/16 | 36 | 216 | 129.6 | 238.46 | 479.52 | 336.1 | 672.3 | 467.8 | 935.7 | 707.85 |

| 1-1/2 | 38 | 228 | 136.8 | 265.7 | 534.28 | 374.4 | 748.7 | 521.3 | 1042.5 | 788.98 |

| 1-9/16 | 40 | 240 | 144 | 294.4 | 592 | 414.5 | 829.1 | 577.6 | 1155.2 | 869.36 |

| 1-5/8 | 42 | 252 | 151.2 | 324.58 | 652.68 | 457.7 | 915.3 | 636.8 | 1273.6 | 959.3 |

| 1-3/4 | 44 | 264 | 158.4 | 356.22 | 716.32 | 502.7 | 999.6 | 698.9 | 1398 | 1111.25 |

| 1-13/16 | 46 | 276 | 165.6 | 389.34 | 782.92 | 548.8 | 1097.6 | 763.9 | 1527.8 | 1152.07 |

| 1-7/8 | 48 | 288 | 172.8 | 423.94 | 852.48 | 597.8 | 1195.6 | 831.7 | 1663.5 | 1256.26 |

| 2 | 50 | 300 | 180 | 460 | 926.09 | 648.8 | 1293.6 | 902.5 | 1805 | 1360.41 |

| 2-1/16 | 52 | 312 | 187.2 | 497.54 | 1000.48 | 697.63 | 1395.26 | 976.14 | 1952.28 | 1485.61 |

| 2-1/8 | 54 | 324 | 194.4 | 536.54 | 1078.92 | 752.33 | 1504.66 | 1052.68 | 2105.36 | 1648.08 |

| 2-3/16 | 56 | 336 | 201.6 | 577.02 | 1160.32 | 809.09 | 1618.18 | 1132.1 | 2264.2 | 1715.97 |

| 2-5/16 | 58 | 348 | 208.8 | 618.98 | 1244.68 | 867.91 | 1735.82 | 1214.4 | 2428.8 | 1844.5 |

| 2-3/8 | 60 | 360 | 216 | 662.4 | 1332 | 928.8 | 1857.6 | 1299.6 | 2599.2 | 1973.29 |

| 2-7/16 | 62 | 372 | 223.2 | 707.3 | 1422.28 | 991.75 | 1983.5 | 1387.68 | 2775.36 | 2101.56 |

| 2-1/2 | 64 | 384 | 230.4 | 753.66 | 1515.52 | 1056.77 | 2113.54 | 1478.66 | 2957.32 | 2298.47 |

| 2-9/16 | 66 | 396 | 237.6 | 801.5 | 1611.72 | 1123.85 | 2247.7 | 1572.52 | 3145.04 | 2398.1 |

| 2-11/16 | 68 | 408 | 244.8 | 850.82 | 1710.88 | 1192.99 | 2385.98 | 1669.26 | 3338.52 | 2522.88 |

| 2-3/4 | 70 | 420 | 252 | 901.6 | 1813 | 1264.2 | 2528.4 | 1768.9 | 3537.8 | 2697.65 |

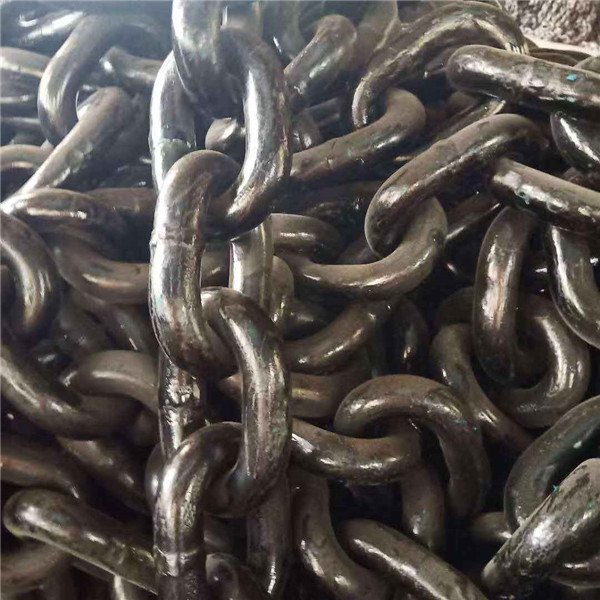

Stud Link and Studless Link Anchor Chain are widely used on Floating Equipment, Ships(Boats), Oil Rigs and Mooring Buoys.

Lift-Sunny supply wide range of sizes and grades: Grade U1/ U2 / U3 from 12.5mm to 162mm; Grade ORQ / R3 /R3S / R4 from 58mm to 162mm.

Application

Stud Link and Studless Link Anchor Chain are widely used on Floating Equipment, Ships(Boats), Oil Rigs and Mooring Buoys.

Package and shipping

1). Gunny bag, inside PVC bag and outside gunny bag +pallet

2). Wooden case or pp ton woven bag

3). Steel drum

Equipment

Manufacturing process quality control from raw material to final product.

Whole set drawing approved by all IACS members; Material Fatigue Test on request; Stress Analysis on request; Stress actual test on quest.

Magnetic power testing, ultrasonic testing, and fluorescent penetrant inspection.

Load test machine up to 4000Ton.

Studless link anchor chain is a type of chain commonly used in marine and offshore industries for anchoring vessels and offshore structures. It is designed to provide reliable strength, durability, and resistance to the harsh conditions of the marine environment.

Key Features of Studless Link Anchor Chain:

- Construction: Studless link anchor chain is made up of a series of interlocking links without protruding studs or fittings. This design provides a smooth profile, minimizing the risk of snagging or damage to the chain and ensuring consistent strength throughout its length.

- High Tensile Strength: Studless link anchor chain is manufactured from high-grade steel, typically alloy steel or carbon steel, to deliver exceptional tensile strength. This allows it to withstand the heavy loads and forces encountered during anchoring operations.

- Uniform Load Distribution: The absence of studs in the chain design allows for uniform distribution of the load across the links. This helps prevent localized stress concentrations, reducing the risk of chain failure and ensuring reliable and safe anchoring.

- Corrosion Resistance: Studless link anchor chain is typically treated with protective coatings, such as hot-dip galvanization or specialized marine-grade coatings, to enhance corrosion resistance. These coatings provide a barrier against rust and degradation caused by exposure to seawater and other corrosive elements.

- Flexibility and Bending Properties: Despite its strength, studless link anchor chain retains a certain degree of flexibility, allowing it to bend and adapt to the shape of the anchor and the seabed. This flexibility helps ensure proper engagement and holding power during anchoring.

- Certification and Standards: Studless link anchor chain is manufactured in accordance with industry standards and regulations, such as the International Organization for Standardization (ISO) standards and classification society requirements. Chains often undergo rigorous testing and certification to meet specific strength and quality standards.

- Chain Accessories: Studless link anchor chain is compatible with various chain accessories, such as shackles, swivels, and anchor connectors, which facilitate proper attachment to anchors and anchor handling equipment.

Studless link anchor chain is available in different sizes, determined by the diameter of the chain, and is specified based on the vessel’s size and the required anchor holding capacity. Regular inspection, maintenance, and proper handling are essential to ensure the integrity and reliability of the chain over time.

When selecting studless link anchor chain, it is crucial to consider factors such as the vessel’s size, anchor type, operating conditions, and applicable industry regulations to ensure optimal performance and safety during anchoring operations.