Multi leg chain slings are an essential component of any offshore lifting operation. These slings are designed to distribute the weight of a load across multiple legs, providing a more stable and secure lifting solution. In this article, we will discuss the benefits of using multi leg chain sling for offshore lifting operations, the different types of multi leg chain sling available, and how to properly inspect and maintain them.

Benefits of Multi Leg Chain Sling

Multi leg chain slings offer several benefits over traditional single leg slings. First and foremost, they are able to distribute the weight of a load more evenly, reducing the risk of overload on any one leg. This makes them an ideal solution for lifting heavier loads, as well as for more complex lifting operations.

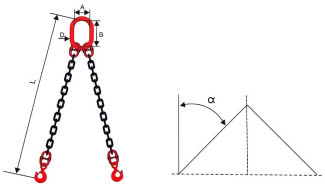

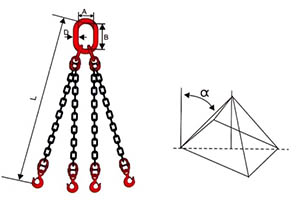

Additionally, multi leg chain slings are more flexible than single leg slings, allowing them to be used in a wider variety of applications. They can be configured in a number of different ways, depending on the requirements of the lift. For example, a four leg chain sling can be used to lift a load that is both heavy and awkwardly shaped.

Types of Multi Leg Chain Slings

There are several different types of multi leg chain sling available, each designed for specific lifting applications. The most common types include:

- Three leg chain slings: These slings are often used for lifting triangular loads, such as pipes or containers.

- Four leg chain slings: These slings are ideal for lifting loads that are both heavy and awkwardly shaped, such as machinery or equipment.

- Six leg chain slings: These slings are used for lifting cylindrical loads, such as drums or tanks.

- Eight leg chain slings: These slings are used for lifting large and heavy loads, such as steel structures or offshore platforms.

Inspection and Maintenance

Like all lifting equipment, multi leg chain slings must be properly inspected and maintained to ensure their safe and reliable operation. It is important to inspect the slings before each use, looking for any signs of wear or damage. If any defects are found, the slings should be taken out of service immediately.

In addition to regular inspections, multi leg chain slings should be properly maintained to ensure their longevity. This includes cleaning the slings after each use, storing them in a dry and secure location, and lubricating them as needed.

Choosing the Right Multi Leg Chain Sling

When choosing the right multi leg chain sling for a specific lifting operation, it is important to consider several factors. These include the weight and shape of the load, as well as the environment in which the lifting operation will take place.

For example, a three leg chain sling may be appropriate for lifting a triangular load, but it may not be suitable for a cylindrical load. Similarly, a six leg chain sling may be the right choice for lifting a cylindrical load, but it may not be the best option for a load that is heavy and awkwardly shaped.

It is also important to consider the environment in which the lifting operation will take place. Offshore lifting operations often involve harsh weather conditions and exposure to saltwater, which can cause corrosion and damage to lifting equipment. Choosing a multi leg chain sling that is specifically designed for offshore use can help ensure its longevity and safe operation.

Training and Certification

In addition to choosing the right type of multi leg chain sling, it is important to ensure that all personnel involved in the lifting operation are properly trained and certified. This includes riggers, crane operators, and other lifting personnel.

Training should cover not only the proper use of multi leg chain slings, but also the inspection and maintenance procedures that are necessary to ensure their safe operation. Certification should be provided by a recognized training organization and should be renewed on a regular basis to ensure ongoing competence.

Conclusion

Multi leg chain slings are an essential component of any offshore lifting operation. They offer several benefits over traditional single leg slings, including the ability to distribute weight more evenly and flexibility in configuration. By choosing the right type of multi leg chain sling and properly inspecting and maintaining it, you can ensure safe and reliable lifting operations offshore.

Related Products