If you’re looking for a reliable and efficient anchor chain for your vessel, consider a studless link anchor chain. Unlike traditional chains, these chains have no protrusions or studs, making them more secure and easier to handle. In this article, we’ll delve deeper into the advantages of studless link anchor chains and why they are becoming the preferred choice for modern marine applications.

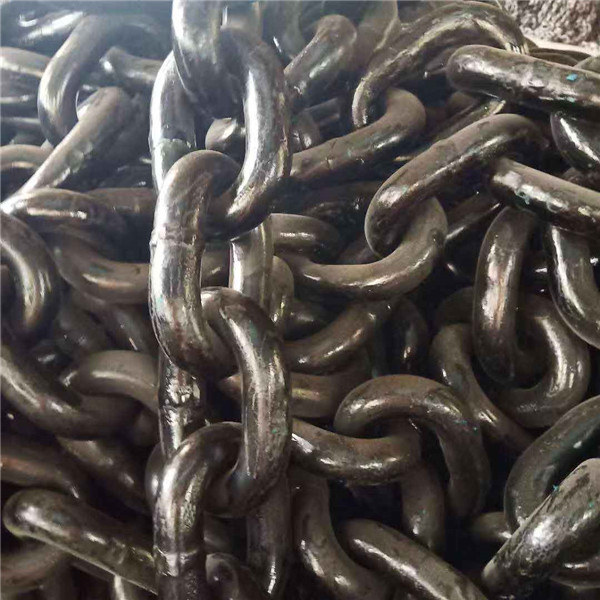

What is a Studless Link Anchor Chain?

A studless link anchor chain is a type of chain used in anchoring systems for ships and other large vessels. It consists of a series of interlocking links with no protrusions, making it smoother and safer to handle. The chain is designed to withstand high loads and resist wear and tear, making it ideal for heavy-duty applications.

Advantages of Studless Link Anchor Chains

1. Safer and Easier to Handle

The lack of studs and protrusions on studless link anchor chain makes them safer and easier to handle than traditional chains. They are less likely to snag on the deck or other equipment, reducing the risk of accidents and injuries. Additionally, their smooth surface reduces wear and tear on the chain and other components, leading to longer service life and reduced maintenance costs.

2. Greater Strength and Load Capacity

Studless link anchor chains have greater strength and load capacity than traditional chains. They are designed to withstand high loads and stresses, making them ideal for heavy-duty applications. Additionally, the lack of studs and protrusions on the chain reduces stress concentrations, leading to improved fatigue resistance and longer service life.

3. Enhanced Corrosion Resistance

Studless link anchor chains are typically made from high-quality steel that is resistant to corrosion. This reduces the risk of rust and other types of corrosion, leading to longer service life and reduced maintenance costs. Additionally, some manufacturers offer special coatings and treatments to further enhance the corrosion resistance of their chains.

4. More Efficient and Cost-Effective

Studless link anchor chains are more efficient and cost-effective than traditional chains. Their smoother surface reduces drag and friction, leading to improved performance and reduced fuel consumption. Additionally, their longer service life and reduced maintenance costs result in lower total cost of ownership over the life of the chain.

Uses of Studless Link Anchor Chain

Studless link anchor chains are used in a variety of marine applications, including:

- Anchoring systems for ships and large vessels

- Offshore mooring systems

- Towing and winching operations

- Deep-sea mining operations

- Oil and gas exploration and production

When choosing a studless link anchor chain, there are several factors to consider, including:

- Chain Grade: Studless link anchor chains come in various grades, each with different strength and load capacity. The higher the grade, the stronger the chain, and the more it can withstand heavy loads. It is essential to select the appropriate grade for your specific application.

- Chain Diameter: The diameter of the chain determines its strength and load capacity. A thicker chain will be stronger and more resistant to wear and tear than a thinner chain. It is crucial to select the appropriate diameter for your specific application.

- Chain Length: The length of the chain will depend on the depth of the water and the size of the vessel. It is essential to select the appropriate length to ensure that the chain can reach the seabed and provide sufficient holding power.

- Corrosion Resistance: As mentioned earlier, studless link anchor chains are typically made from high-quality steel that is resistant to corrosion. However, some manufacturers offer special coatings and treatments to further enhance the corrosion resistance of their chains. It is crucial to select a chain with adequate corrosion resistance to ensure that it lasts longer and requires less maintenance.

- Certification: Studless link anchor chains must meet certain standards and certifications to ensure their quality and safety. It is crucial to select a chain that has been certified by reputable organizations such as the American Bureau of Shipping (ABS) or the International Organization for Standardization (ISO).

Maintenance of Studless Link Anchor Chains

Studless link anchor chains are used in marine applications, particularly for anchoring ships. Proper maintenance of these chains is important to ensure their safe and effective use. Here are some tips for maintaining studless link anchor chains:

- Regular Inspection: Inspect the chain regularly for any signs of damage, wear, or corrosion. Check for any bent or twisted links, elongation, or deformations. This can be done visually or by using non-destructive testing methods such as ultrasonic testing.

- Cleaning: Clean the chain regularly to remove any saltwater, dirt, or debris that may have accumulated on it. This can be done using freshwater and a soft-bristled brush. Avoid using harsh chemicals or abrasives as they can damage the chain.

- Lubrication: Apply a suitable lubricant to the chain to reduce friction and wear. This helps to extend the life of the chain and also prevents corrosion. Use a lubricant that is recommended by the chain manufacturer.

- Storage: Store the chain properly when not in use. Keep it dry and free from moisture to prevent corrosion. It is also important to store the chain in a well-ventilated area to prevent the growth of mold and mildew.

- Repair or Replace: If any damage or wear is detected during inspection, it is important to repair or replace the chain as necessary. Do not continue to use a damaged or worn chain as this can compromise its strength and integrity.

Conclusion

Studless link anchor chains are a safer, stronger, and more efficient option for anchoring systems in modern marine applications. Their smooth surface, enhanced corrosion resistance, and greater load capacity make them the preferred choice for ship owners and operators worldwide. If you’re looking for a reliable and efficient anchor chain for your vessel, consider a studless link anchor chain.

Related Products