Billet tong

| Rated load (t) | Applied range(mm) | Billet smallest thickness(mm) | Span (mm) | Max dimension (mm) | Self weight (kg) | |

| W | H | |||||

| 3 | 100-300 | 60 | 800 | 1200 | 1600 | 350 |

| 5 | 100-300 | 70 | 800 | 1200 | 1800 | 500 |

| 5 | 170-350 | 80 | 800 | 1300 | 1800 | 600 |

| 5 | 450-600 | 100 | 800 | 1200 | 1800 | 600 |

| 5 | 650-1000 | 140 | 800 | 1500 | 2300 | 850 |

| 8 | 150-450 | 90 | 1200 | 2000 | 2400 | 1300 |

| 8 | 450-600 | 110 | 1200 | 1600 | 2500 | 1300 |

| 8 | 450-750 | 130 | 1200 | 1600 | 2200 | 1350 |

| 10 | 450-900 | 140 | 1500 | 1900 | 2600 | 2200 |

| 10 | 650-1000 | 150 | 1500 | 1600 | 2600 | 1800 |

| 10 | 700-1100 | 160 | 1500 | 1700 | 2600 | 1900 |

| 12 | 450-750 | 120 | 2000 | 1800 | 2400 | 2600 |

| 12 | 235-800 | 150 | 2000 | 2300 | 3000 | 2700 |

| 16 | 450-750 | 120 | 2500 | 2000 | 2700 | 3600 |

| 16 | 450-900 | 140 | 2500 | 2100 | 3000 | 3800 |

| 16 | 650-1000 | 150 | 2500 | 2000 | 2700 | 3800 |

| 16 | 600-1100 | 190 | 2500 | 2400 | 3100 | 4200 |

| 16 | 850-1250 | 160 | 2500 | 2000 | 3000 | 4200 |

| 20 | 700-1100 | 150 | 3000 | 2200 | 3200 | 4600 |

| 20 | 800-1300 | 170 | 3000 | 2200 | 3400 | 4800 |

| 20 | 950-1400 | 160 | 3000 | 2500 | 3500 | 4800 |

Note: the model which not listed in above table also can be designed according to customer’s requirements.

Application:

shipyard, steel structure installation, steel market, mechanical processing, steel plate welding, steel plate cutting, steel plate horizontal handling, steel plate vertical moving and other work places need such products.

Attention :

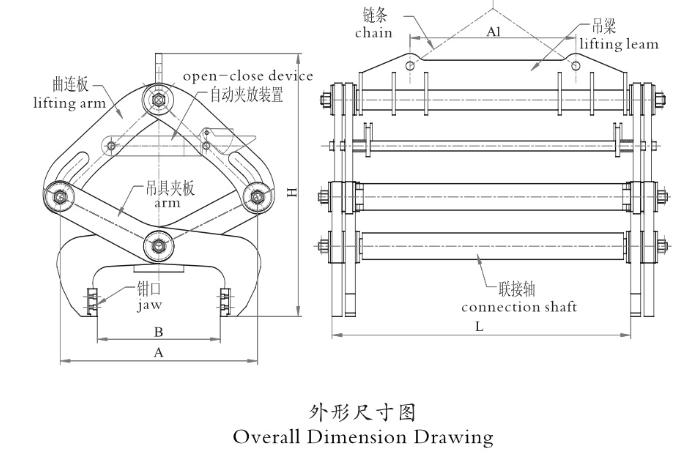

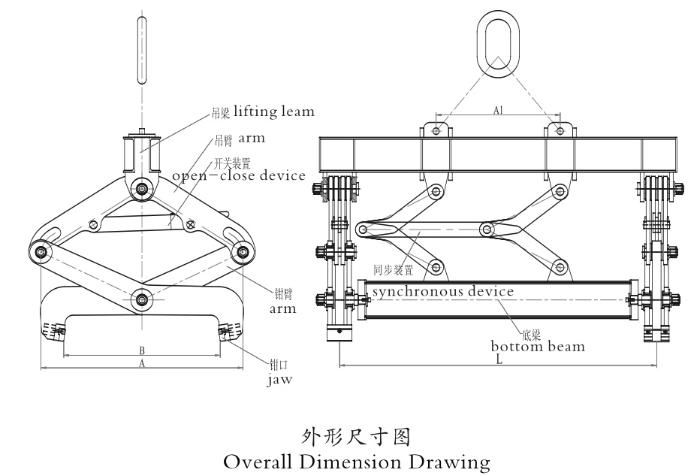

- Billet( plate) lifter is used for lifting steel billet, aluminum plate &copperplate.

- Clamp force is produced by lever mechanism through gravity of slab.

- The opening and close of clamp is controlled by auto latch mechanism.

- Single or multiple slabs can be lifted.

- Single in structure, convenient and agile in usage.

- The wide range of available square billet is 100mm-400mm.

- 1T to 60T billet handing capacity depending on the size of the lifter

Shop view:

What is a steel slab clamp billet lifting clamp, and how does it work?

A steel slab clamp billet lifting clamp is a device used to lift and transport steel slabs, billets, and other heavy materials. It is typically used in steel mills, foundries, and other manufacturing facilities where large and heavy materials need to be moved.

The clamp consists of two jaws that are connected by a hinge and can be opened and closed using a lever or other mechanism. When the jaws are closed, they grip onto the material, creating a secure hold that allows it to be lifted and transported. The clamp is attached to a crane or other lifting equipment using a shackle or other connection point.

The design of the clamp is such that it distributes the weight of the material evenly across the jaws, minimizing the risk of damage to the material or the clamp itself. This allows for efficient and safe transportation of heavy materials, reducing the risk of accidents and injuries in the workplace.

What is the weight capacity of a steel slab clamp billet lifting clamp?

The weight capacity of a steel slab clamp billet lifting clamp can vary depending on the specific model and manufacturer. However, these clamps are typically designed to lift and transport heavy materials weighing anywhere from a few hundred kilograms to several tons.

Some models of steel slab clamp billet lifting clamps have a weight capacity of up to 20 tons or more, while others may have a lower weight capacity. It is important to check the specifications of a particular clamp to ensure that it is suitable for the weight of the material being lifted.

It is also important to note that the weight capacity of a clamp is affected by factors such as the angle at which the clamp is attached to the material and the condition of the material being lifted. Therefore, it is important to use the clamp within its specified weight capacity and to follow all safety guidelines when lifting heavy materials.

What are the safety features of a steel slab clamp billet lifting clamp?

Steel slab clamp billet lifting clamps generally have several safety features to ensure safe lifting and transportation of heavy materials. Some common safety features include:

- Locking mechanism: The clamp is designed to lock onto the material being lifted, creating a secure hold that minimizes the risk of the material slipping or falling.

- Safety latch: Many clamps have a safety latch that prevents the clamp from accidentally opening during lifting.

- Load rating: The clamp is typically rated based on the weight of the material it can safely lift, ensuring that it is not overloaded and that the weight is evenly distributed.

- Durability: The clamp is made from high-quality materials that can withstand heavy use and resist wear and tear.

- Inspection and maintenance: Regular inspection and maintenance are required to ensure that the clamp is in good working condition and that all safety features are functioning properly.

- Operator training: Operators should be properly trained in the safe use of the clamp and should follow all safety guidelines and procedures.

- Warning labels: The clamp should have clear warning labels indicating its weight capacity and any other important safety information.

Overall, steel slab clamp billet lifting clamps are designed to be safe and reliable tools for lifting and transporting heavy materials. It is important to follow all safety guidelines and procedures to prevent accidents and injuries in the workplace.

What are some common applications of steel slab clamp billet lifting clamps?

Steel slab clamp billet lifting clamps are commonly used in a variety of industrial applications where heavy materials need to be lifted and transported. Some common applications include:

- Steel mills: Steel slab clamp billet lifting clamps are often used in steel mills to lift and transport steel slabs, billets, and other heavy materials.

- Foundries: Foundries use these clamps to move heavy castings and other metal components during the manufacturing process.

- Construction sites: Steel slab clamp billet lifting clamps are useful for moving heavy steel beams, columns, and other construction materials on construction sites.

- Ports and shipping yards: These clamps are frequently used to load and unload heavy cargo from ships and trucks.

- Warehouses and distribution centers: Steel slab clamp billet lifting clamps are used to move heavy pallets, crates, and other materials in warehouses and distribution centers.

- Mining and quarrying: These clamps are used to lift and transport heavy rocks, boulders, and other materials in mining and quarrying operations.

- Recycling facilities: Steel slab clamp billet lifting clamps are useful for moving scrap metal and other heavy materials in recycling facilities.

Overall, steel slab clamp billet lifting clamps are versatile tools that can be used in a wide range of industrial and commercial applications where heavy materials need to be lifted and transported.

How do you maintain and care for steel slab clamp billet lifting clamps to ensure their longevity?

Proper maintenance and care are essential to ensure the longevity and safe operation of steel slab clamp billet lifting clamps. Here are some tips for maintaining and caring for these clamps:

- Regular inspection: Inspect the clamp before and after each use to check for any signs of wear or damage. Look for cracks or other signs of damage to the jaws, hinge, and other components.

- Cleaning: Clean the clamp regularly to remove dirt, dust, and other debris that can cause wear and tear on the components. Use a dry cloth or brush to remove any debris, and avoid using water or other liquids that can cause rust or corrosion.

- Lubrication: Apply lubricant to the hinge and other moving parts to reduce friction and prevent wear and tear. Use a light oil or grease that is compatible with the materials used in the clamp.

- Storage: Store the clamp in a dry, protected location when it is not in use to prevent rust and corrosion. Avoid storing the clamp in damp or humid environments.

- Replacement of parts: Replace any worn or damaged components as soon as possible to prevent further damage and ensure the safe operation of the clamp.

- Operator training: Provide proper training to operators to ensure that they know how to use the clamp safely and correctly. Encourage them to report any issues or concerns with the clamp immediately.

By following these tips, you can help ensure that your steel slab clamp billet lifting clamps remain in good working condition and operate safely and efficiently for years to come.