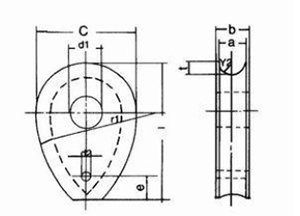

Wire rope Heavy duty Malleable Casting DIN3091 thimble

|

SIZE | Dimensions mm | |||||

| mm | A | B | C | D1 | T | L | N |

| 8 | 9 | 15 | 40 | 14 | 4.5 | 56 | 48 |

| 10 | 11 | 17.5 | 50 | 18 | 6 | 70 | 60 |

| 12 | 13 | 20 | 60 | 21 | 7.5 | 84 | 72 |

| 14 | 16 | 23.5 | 70 | 25 | 9 | 98 | 84 |

| 16 | 18 | 26 | 80 | 28 | 10.5 | 110 | 96 |

| 18 | 20 | 28.5 | 90 | 31 | 12 | 130 | 110 |

| 20 | 22 | 31 | 100 | 35 | 13.5 | 140 | 120 |

| 22 | 24 | 33.5 | 110 | 38 | 15 | 150 | 130 |

| 24 | 26 | 36 | 120 | 41 | 16.5 | 170 | 140 |

| 26 | 29 | 39.5 | 130 | 44 | 18 | 180 | 160 |

| 28 | 31 | 42 | 140 | 47 | 20 | 200 | 170 |

| 32 | 35 | 47 | 160 | 53 | 23 | 220 | 190 |

| 36 | 40 | 53 | 180 | 59 | 26 | 250 | 220 |

| 40 | 44 | 58 | 200 | 65 | 29 | 280 | 240 |

| 44 | 48 | 63 | 220 | 70 | 32 | 310 | 260 |

Thimbles mainly are used for Wire rope fittings, Chain fittings, Marine hardware fitting.

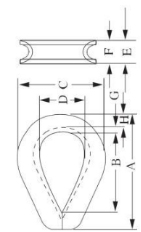

WT thimble

|

ROPE DIA. | DIMENSIONS | ||||||

| (inch) | ||||||||

| (inch) | A | B | C | D | E | F | G | H |

| 1/8 | 1.94 | 1.31 | 1.06 | 0.69 | 0.25 | 0.16 | 0.05 | 0.13 |

| 3/16 | 1.94 | 1.31 | 1.06 | 0.69 | 0.31 | 0.22 | 0.05 | 0.13 |

| 1/4 | 1.94 | 1.31 | 1.06 | 0.69 | 0.38 | 0.28 | 0.05 | 0.13 |

| 5/16 | 2.13 | 1.5 | 1.25 | 0.81 | 0.44 | 0.34 | 0.05 | 0.13 |

| 3/8 | 2.38 | 1.63 | 1.47 | 0.94 | 0.53 | 0.41 | 0.06 | 0.16 |

| 1/2 | 2.75 | 1.88 | 1.75 | 1.13 | 0.69 | 0.53 | 0.08 | 0.19 |

| 5/8 | 3.5 | 2.25 | 2.38 | 1.38 | 0.91 | 0.66 | 0.13 | 0.34 |

| 3/4 | 3.75 | 2.5 | 2.69 | 1.63 | 1.08 | 0.78 | 0.14 | 0.34 |

| 7/8 | 5 | 3.5 | 3.19 | 1.88 | 1.27 | 0.94 | 0.16 | 0.44 |

| 1 | 5.69 | 4.25 | 3.75 | 2.5 | 1.39 | 1.06 | 0.16 | 0.41 |

| 1-1/8-1-1/4 | 6.25 | 4.5 | 4.31 | 2.75 | 1.75 | 1.31 | 0.22 | 0.5 |

Wire rope thimbles are just one of the many types of wire rope fittings (ferrules, shackles, terminals, etc.)

Thimbles are perfect for wire ropes terminating in a loop and are one of the most commonly used end fittings for steel cable. They are used to help protect the steel wire-rope which forms the eye, and therefore will greatly extend the working life of the rope, they also add extra rigidity to a soft loop making it stronger and much easier to attach wherever it is needed.

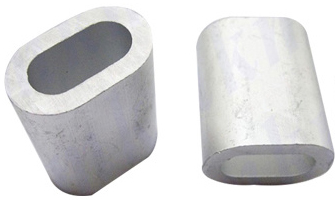

Wire rope ferrule

US Type Aluminium Sleeve Cable Crimps/Wire Rope Ferrules

Material: Aluminum

Surface: Zinc plated, Self

Finish: Machine polished

|

|||||

| Wire rope Dia. | A(mm) | B(mm) | S(mm) | L(mm) | Weight |

| (mm) | kgs/1000pcs | ||||

| 1 | 1.2 | 2.4 | 0.65 | 5 | 0.098 |

| 1.5 | 1.7 | 3.4 | 0.75 | 6 | 0.176 |

| 2 | 2.2 | 4.4 | 0.85 | 7 | 0.285 |

| 2.5 | 2.7 | 5.4 | 1.05 | 9 | 0.439 |

| 3 | 3.3 | 6.6 | 1.25 | 11 | 0.907 |

| 3.5 | 3.8 | 7.6 | 1.5 | 13 | 1.18 |

| 4 | 4.4 | 8.8 | 1.7 | 14 | 1.63 |

| 4.5 | 4.9 | 9.8 | 1.9 | 16 | 2.39 |

| 5 | 5.5 | 11 | 2.1 | 18 | 3.62 |

| 6 | 6.6 | 13.2 | 2.5 | 21 | 5.87 |

| 6.5 | 7.2 | 14.4 | 2.7 | 23 | 7.18 |

| 7 | 7.8 | 15.6 | 2.9 | 25 | 9.83 |

| 8 | 8.8 | 17.6 | 3.3 | 28 | 12.96 |

| 9 | 9.9 | 19.8 | 3.7 | 32 | 18.94 |

| 10 | 10.9 | 21.8 | 4.1 | 35 | 24.09 |

| 11 | 12.1 | 24.2 | 4.5 | 39 | 35.35 |

| 12 | 13.2 | 26.4 | 4.9 | 42 | 44.18 |

| 13 | 14.2 | 28.4 | 5.4 | 46 | 59.86 |

| 14 | 15.3 | 30.6 | 5.8 | 49 | 73.5 |

| 16 | 17.5 | 35 | 6.7 | 56 | 111 |

| 18 | 19.6 | 39.2 | 7.6 | 63 | 156 |

| 20 | 21.7 | 43.4 | 8.4 | 70 | 217 |

| 22 | 24.3 | 48.6 | 9.2 | 77 | 292 |

| 24 | 26.4 | 52.8 | 10 | 84 | 376 |

| 26 | 28.5 | 57 | 10.9 | 91 | 481 |

| 28 | 31 | 62 | 11.7 | 98 | 603 |

| 30 | 33.1 | 66.2 | 12.5 | 105 | 739 |

| 32 | 35.2 | 70.4 | 13.4 | 112 | 897 |

| 34 | 37.8 | 75.6 | 14.2 | 119 | 1077 |

| 36 | 39.8 | 79.6 | 15 | 126 | 1275 |

| 38 | 41.9 | 83.8 | 15.8 | 133 | 1503 |

| 40 | 44 | 88 | 16.6 | 140 | 1734 |

| 42 | 46.2 | 92.4 | 17.5 | 147 | 2024 |

| 44 | 48.4 | 96.8 | 18.3 | 154 | 2314 |

| 46 | 50.6 | 101.2 | 19.2 | 161 | 2662 |

| 48 | 52.8 | 105.6 | 20 | 168 | 3010 |

| 50 | 55 | 110 | 20.8 | 175 | 3412 |

| 52 | 57.2 | 114.4 | 21.6 | 182 | 3813 |

| 54 | 59.4 | 118.8 | 22.5 | 189 | 4293 |

| 56 | 61.6 | 123.2 | 23.3 | 196 | 4772 |

| 58 | 63.8 | 127.6 | 24.2 | 203 | 5326 |

| 60 | 66 | 132 | 25 | 210 | 5880 |

Din3093 ferrules sleeve wildly used for industry,marine, construction industry, mining industry, etc. mainly used for steel wire rope fastener.

As for small size steel wire rope, you can choice above two methods to use.

We have many type aluminium sleeves, such as: EN 13411-3(DIN3093), oval shape aluminium sleeve, Hourglass sleeve, aluminium stop buttons, Aluminium ferrules Jis type, and copper ferrules.

Application

Used on wire rope and fix the hole of the cable.

Understanding Thimble and Ferrule in Heavy-Duty Applications

In heavy-duty applications, thimbles and ferrules are used to protect wire ropes from the effects of heavy loads, vibration, and harsh weather conditions. They are commonly used in construction, cargo handling, and marine industries. Thimbles and ferrules work together to create a strong and secure connection between the wire rope and the anchor point or load.

When a wire rope is subjected to heavy loads, it can become stretched or distorted, resulting in wear and tear. A thimble helps to distribute the load evenly across the wire rope, preventing it from becoming damaged or distorted. Ferrules, on the other hand, are used to secure the wire rope to the anchor point or load. Ferrules grip the wire rope tightly, preventing it from slipping or becoming dislodged.

How Thimble and Ferrule Work Together

Thimbles and ferrules work together to protect the wire rope and create a secure connection. The thimble is inserted into the eye of the wire rope, which prevents the wire rope from becoming distorted when it is bent. The ferrule is then placed over the thimble and wire rope, providing a secure connection between the wire rope and the anchor point or load.

When the wire rope is under tension, the thimble helps to distribute the load evenly across the wire rope. This prevents the wire rope from becoming damaged or distorted, which can lead to failure. The ferrule provides a tight grip on the wire rope, preventing it from slipping or becoming dislodged. Together, thimbles and ferrules ensure a strong and secure connection between the wire rope and the anchor point or load.

The Benefits of Using Thimble and Ferrule in Heavy-Duty Applications

Using thimbles and ferrules in heavy-duty applications provides several benefits. Firstly, they protect the wire rope from wear and tear caused by friction, bending, or twisting. This prolongs the lifespan of the wire rope, reducing the need for frequent replacements. Secondly, thimbles and ferrules distribute the load evenly across the wire rope, preventing it from becoming distorted or damaged when it is bent. This ensures that the wire rope remains strong and secure, even under heavy loads.

Thirdly, thimbles and ferrules provide a secure connection between the wire rope and the anchor point or load. This prevents the wire rope from slipping or becoming dislodged, which can lead to accidents and injuries. Finally, thimbles and ferrules are easy to install and maintain, making them a cost-effective solution for heavy-duty applications.

Types of Thimbles and Ferrules

There are several types of thimbles and ferrules available for heavy-duty applications. The most common types of thimbles are standard, heavy-duty, and open. Standard thimbles are used in light-duty applications, while heavy-duty thimbles are used in heavy-duty applications. Open thimbles are used in applications where the wire rope needs to be quickly and easily inserted or removed.

The most common types of ferrules are duplex, aluminum, and copper. Duplex ferrules are used in heavy-duty applications, while aluminum and copper ferrules are used in lighter-duty applications. Aluminum ferrules are lightweight and corrosion-resistant, while copper ferrules are durable and provide a high level of conductivity.

Choosing the Right Thimble and Ferrule for Your Application

Choosing the right thimble and ferrule for your application is essential to ensure that the wire rope remains strong and secure. Factors to consider when choosing the right thimble and ferrule include the size and type of wire rope, the load capacity, the environment in which it will be used, and the type of connection required.

It is important to choose a thimble and ferrule that matches the size of the wire rope. Using a thimble that is too small or too large can lead to distortion or damage to the wire rope. Similarly, using a ferrule that is too small or too large can affect the strength and security of the connection.

Installation and Maintenance of Thimble and Ferrule

Proper installation and maintenance of thimbles and ferrules are essential to ensure that they provide a strong and secure connection. When installing thimbles and ferrules, it is important to follow the manufacturer’s instructions carefully. This includes ensuring that the thimble is inserted correctly into the eye of the wire rope and that the ferrule is tightened to the correct torque.

Regular maintenance is also essential to ensure that thimbles and ferrules remain in good condition. This includes inspecting them regularly for signs of wear and tear, such as cracks or distortion. If any damage is detected, the thimble or ferrule should be replaced immediately.

Importance of Using High-Quality Thimble and Ferrule

Using high-quality thimbles and ferrules is essential to ensure that the wire rope remains strong and secure. Cheap or low-quality thimbles and ferrules can lead to distortion or damage to the wire rope, which can result in failure. High-quality thimbles and ferrules are made from strong and durable materials, such as stainless steel or galvanized steel, and are designed to withstand heavy loads and harsh environments.

In conclusion, thimbles and ferrules are essential components in heavy-duty applications that should not be overlooked. They protect the wire rope from wear and tear, distribute the load evenly, and create a strong and secure connection between the wire rope and the anchor point or load. Choosing the right thimble and ferrule, installing and maintaining them properly, using high-quality components, and avoiding common mistakes are all essential to ensure that they provide a strong and secure connection.