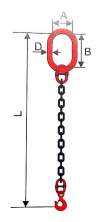

T(8)single-leg chain sling

| Standard | GB/T20652-2006,EN818-2 |  |

| Safety ratio | 4 times | |

| Application range | Lifting | |

| Material | High quality alloy containing Cr, Ni, Mo | |

| Surface treatment | Oiled, blackening, hot dip galvanized, electro galvanized, carburization, polishing |

| Model | Diameter (d)mm | WLL (T) | Master Link (A*B*D) | Weight(Kg/M) |

| DL8-6 | 6 | 1.1 | 60*110*13 | 0.79 |

| DL8-8 | 8 | 2 | 60*110*16 | 1.38 |

| DL8-10 | 10 | 3.15 | 75*135*18 | 2.2 |

| DL8-13 | 13 | 5.3 | 100*180*25 | 3.8 |

| DL8-16 | 16 | 8 | 100*180*25 | 5.63 |

| DL8-20 | 20 | 12.5 | 110*200*32 | 8.6 |

| DL8-22 | 22 | 15 | 140*260*35 | 10.2 |

| DL8-26 | 26 | 21.2 | 180*340*45 | 12.78 |

| DL8-32 | 32 | 31.5 | 190*350*50 | 22.29 |

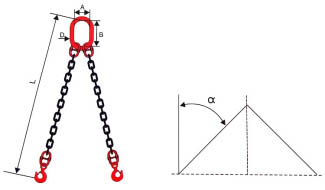

T(8) double- leg chain sling

| Standard | GB/T20652-2006,EN818-2 |  |

| Safety ratio | 4 times | |

| Application range | Lifting | |

| Surface treatment | Oiled, blackening, hot dip galvanized, electro galvanized, carburization, polishing | |

| Note | The rated load capacity will reduce to 20% when the hook go through the chain |

| Model | Diameter (d)mm | WLL(T) | Master link | Weight(Kg/M) | |

| α≤45 |

45<α≤60 | A*B*D | |||

| DL8(2)-6 | 6 | 1.568 | 1.12 | 60*110*13 | 0.79 |

| DL8(2)-8 | 8 | 2.8 | 2 | 75*135*18 | 1.38 |

| DL8(2)-10 | 10 | 4.41 | 3.15 | 90*160*22 | 2.2 |

| DL8(2)-13 | 13 | 7.42 | 5.3 | 100*180*26 | 3.8 |

| DL8(2)-16 | 16 | 10.92 | 7.8 | 110*200*32 | 5.63 |

| DL8(2)-20 | 20 | 15.68 | 11.2 | 160*300*40 | 8.6 |

| DL8(2)-22 | 22 | 21 | 15 | 180*340*45 | 10.2 |

| DL8(2)-26 | 26 | 29.6 | 21.2 | 190*350*50 | 14.87 |

| DL8(2)-32 | 32 | 44.1 | 31.5 | 200*400*60 | 22.29 |

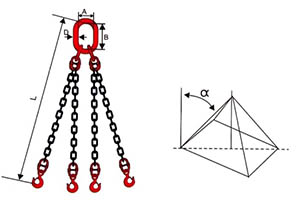

T(8) Four –leg chain sling

| Standard | GB/T20652-2006 |  |

| Safety ratio | 4 times | |

| Surface treatment | Oiled, blackening, hot dip galvanized, electro galvanized, carburization, polishing | |

| Symmetric lifting ,evenly distributed load |

| Model | Diameter (d)mm | WLL(T) | Master link | Weight(Kg/M) | |

| α≤45 |

45<α≤60 | A*B*D | |||

| DL8(4)-6 | 6 | 2.35 | 1.68 | 75*135*18 | 0.79 |

| DL8(4)-8 | 8 | 4.2 | 3 | 90*160*22 | 1.38 |

| DL8(4)-10 | 10 | 6.61 | 4.72 | 100*190*28 | 2.2 |

| DL8(4)-13 | 13 | 11.13 | 7.95 | 110*200*32 | 3.8 |

| DL8(4)-16 | 16 | 16.38 | 11.7 | 140*260*35 | 5.63 |

| DL8(4)-20 | 20 | 23.52 | 16.8 | 190*350*50 | 8.6 |

| DL8(4)-22 | 22 | 31.5 | 22.5 | 190*350*50 | 10.2 |

| DL8(4)-26 | 26 | 44.5 | 31.8 | 200*400*60 | 14 |

| DL8(4)-32 | 32 | 66.15 | 47.25 | 250*460*7 | 22.29 |

Application

Can hold such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, container and other big construction. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

Attention

It is necessary not only to avoid damage to lifting items, but also to prevent damage to the sling.Avoiding spinning or falling, the following conditions should be observed:

A) Single-leg :the lifting point shall be vertically above the center of gravity of the lifting item.

B) In the case of double leg, the lifting point should be located on both sides of the lifting object and above the center of gravity.

A multi-leg chain sling is a lifting tool that consists of several chains with hooks attached to them, all connected to a central master link. This type of sling is ideal for lifting and moving heavy and bulky objects with multiple attachment points. The chains are made of high-strength alloy steel and are available in various lengths and configurations to suit different lifting needs. The multi-leg chain sling is durable, versatile, and easy to use, making it a popular choice in industries such as construction, manufacturing, and transportation. It is capable of lifting heavy loads safely and reliably, and with proper use and maintenance, it can provide long-lasting service for years to come.

Multi-leg chain slings are available in various configurations, including two-leg, three-leg, and four-leg slings, which can be used to lift objects with two, three, or four attachment points respectively. The number of legs needed for a specific lifting job will depend on the weight and shape of the load and the lifting equipment being used.

The hooks on the chains are designed to securely attach to the load, and the central master link allows for easy connection to the lifting equipment. The chains are also adjustable, which allows for precise positioning of the load during lifting and moving operations.

Multi-leg chain slings are designed to meet or exceed industry standards for safety and performance, and they are tested and certified to ensure their reliability and durability. It is essential to follow best practices for their safe and efficient use, including regular inspection and maintenance to ensure that they are in good condition and free from defects.

In conclusion, multi-leg chain slings are a versatile and reliable lifting tool that is suitable for a wide range of applications. They offer high-strength lifting capabilities and can be customized to meet specific lifting needs. With proper care and maintenance, multi-leg chain slings can provide reliable and long-lasting service for years to come.

What safety precautions should be followed when using a multi-leg chain sling

When using a multi-leg chain sling, it is crucial to follow specific safety precautions to ensure the safety of personnel and prevent accidents. Here are some essential safety precautions to keep in mind:

- Inspect the Chain Sling: Before each use, carefully inspect the multi-leg chain sling for any signs of wear, damage, or deformities. Check for broken links, excessive wear, cracks, or distorted components. If any defects are found, remove the sling from service and replace it.

- Determine the Working Load Limit (WLL): Make sure you know the working load limit of the multi-leg chain sling. Avoid exceeding the WLL to prevent overloading and potential failure of the sling.

- Select the Correct Sling Configuration: Ensure that the multi-leg chain sling is properly configured for the intended lifting application. Follow the manufacturer’s instructions and consider factors such as load weight, shape, and lifting points to select the appropriate sling configuration.

- Attach the Sling Correctly: Attach the multi-leg chain sling securely to the load using appropriate fittings, hooks, or attachments. Ensure that the connections are properly aligned and engaged to prevent accidental disengagement during lifting.

- Use Proper Lifting Techniques: Follow safe lifting practices, including using proper lifting equipment, maintaining a stable stance, and ensuring clear communication among team members involved in the lifting operation. Avoid sudden movements or jerks during lifting.

- Protect Against Abrasion and Sharp Edges: Take precautions to protect the multi-leg chain sling from sharp edges, corners, or abrasive surfaces that can cause damage. Use edge protectors, padding, or other suitable measures to prevent abrasion or cutting of the sling.

- Avoid Twisting or Knotting the Sling: Do not twist or knot the chain sling, as this can compromise its strength and lead to failure. Maintain the sling in a straight and untangled configuration during use.

- Control the Load: Keep the load balanced and under control throughout the lifting operation. Prevent swinging or shifting of the load, as it can cause instability and increase the risk of accidents.

- Train Personnel: Ensure that personnel involved in using the multi-leg chain sling are adequately trained in its safe handling and operation. Familiarize them with the manufacturer’s instructions, safety guidelines, and any specific procedures or considerations for the sling.

- Regular Maintenance and Inspection: Establish a routine inspection and maintenance program for the multi-leg chain sling. Regularly inspect the sling for wear, damage, or deterioration and promptly remove any defective slings from service. Clean and lubricate the chain as recommended by the manufacturer.

Following these safety precautions when using a multi-leg chain sling will help minimize the risk of accidents, ensure the safe lifting of loads, and maintain the longevity of the sling. Always refer to the manufacturer’s guidelines and consult with lifting professionals for specific safety recommendations related to your lifting operations.